Leading the Way in Precision Casting Simulation

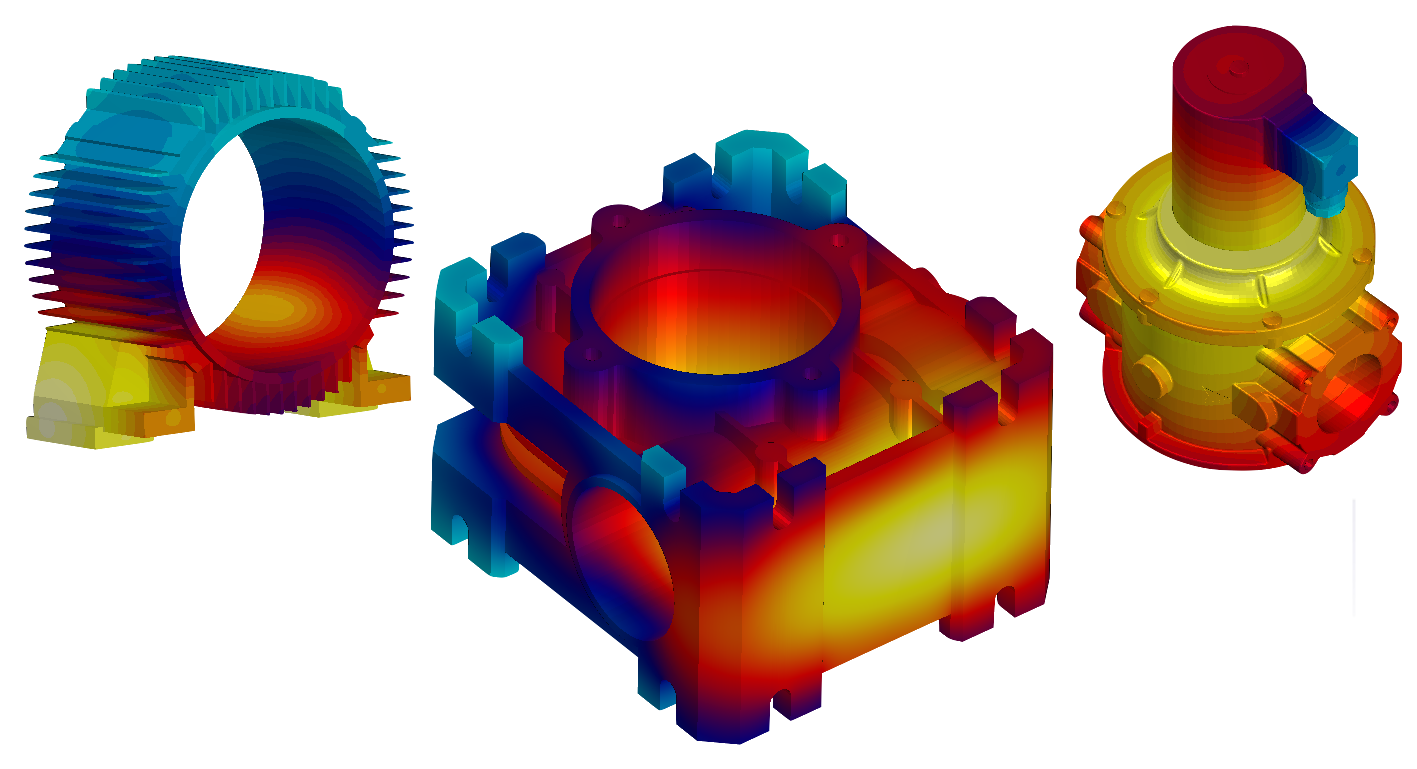

Introducing the pioneering Casting Process CAE system for Windows in Korea, a collaborative creation by KITECH and Cubictek. Our advanced CAE software offers comprehensive simulation capabilities for the entire casting process, encompassing filling, flow, solidification, and cooling behavior

15+

Years of experience

10x

Better Results

WHY Z CAST?

Experience unmatched versatility and more:

From covering all casting processes in one software to offering multi-tab functionality with a single license, providing 3D results, and supporting video output capabilities, we've got you covered—and still more.

simulation

simulation

simulation

simulation

simulation

We’re modernizing  casting, design, and simulation experience with advanced

casting, design, and simulation experience with advanced  tech. Our detailed reports

tech. Our detailed reports  provide precise insights,

provide precise insights,  empowering clients to confidently

empowering clients to confidently  achieve their goals..

achieve their goals..

Simulation Videos

Following are the simulation result videos

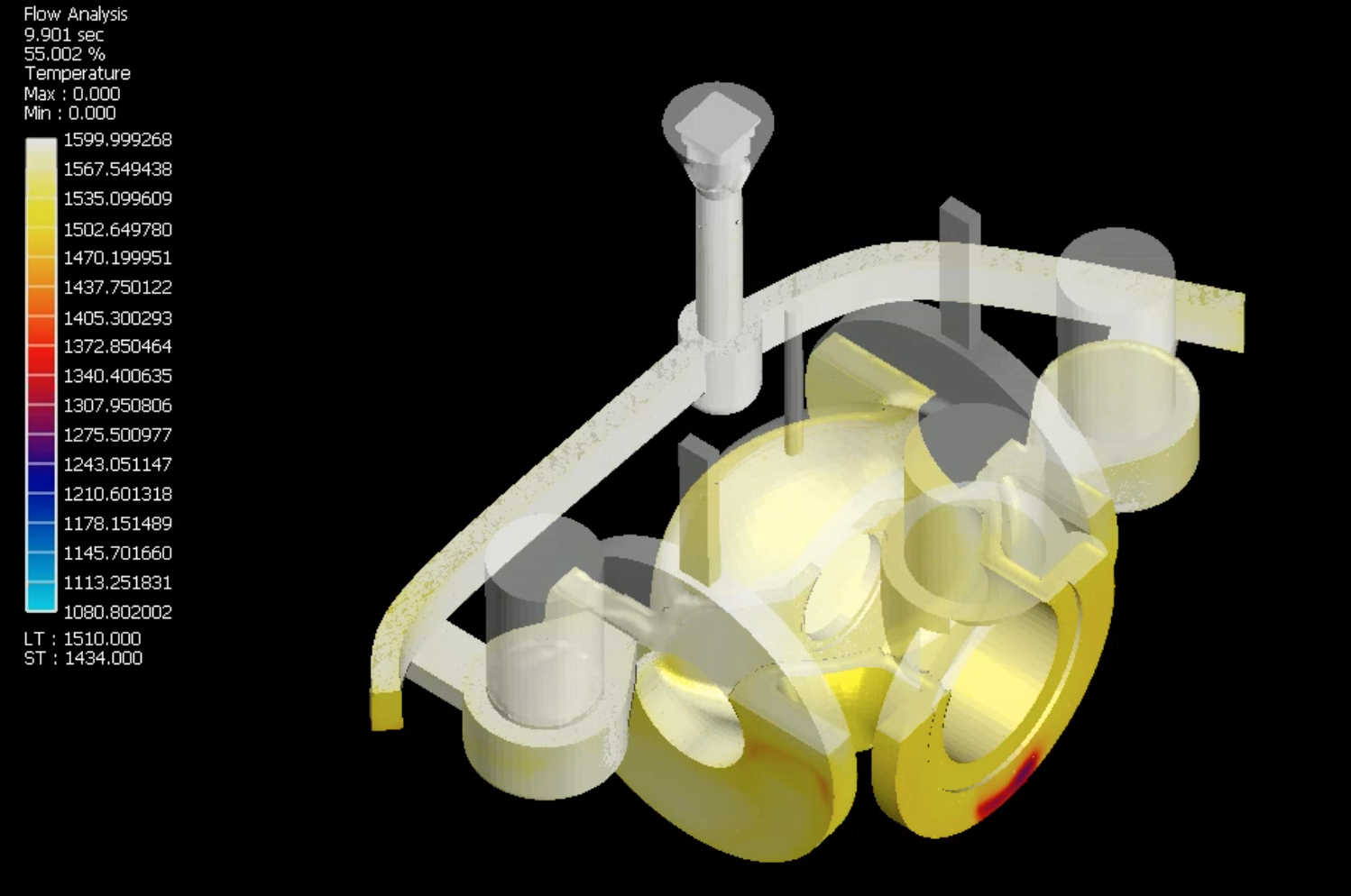

Flow Temperature 20 Sec

Simulation results of metal flow with respect to temperature analyze cold shut chances.

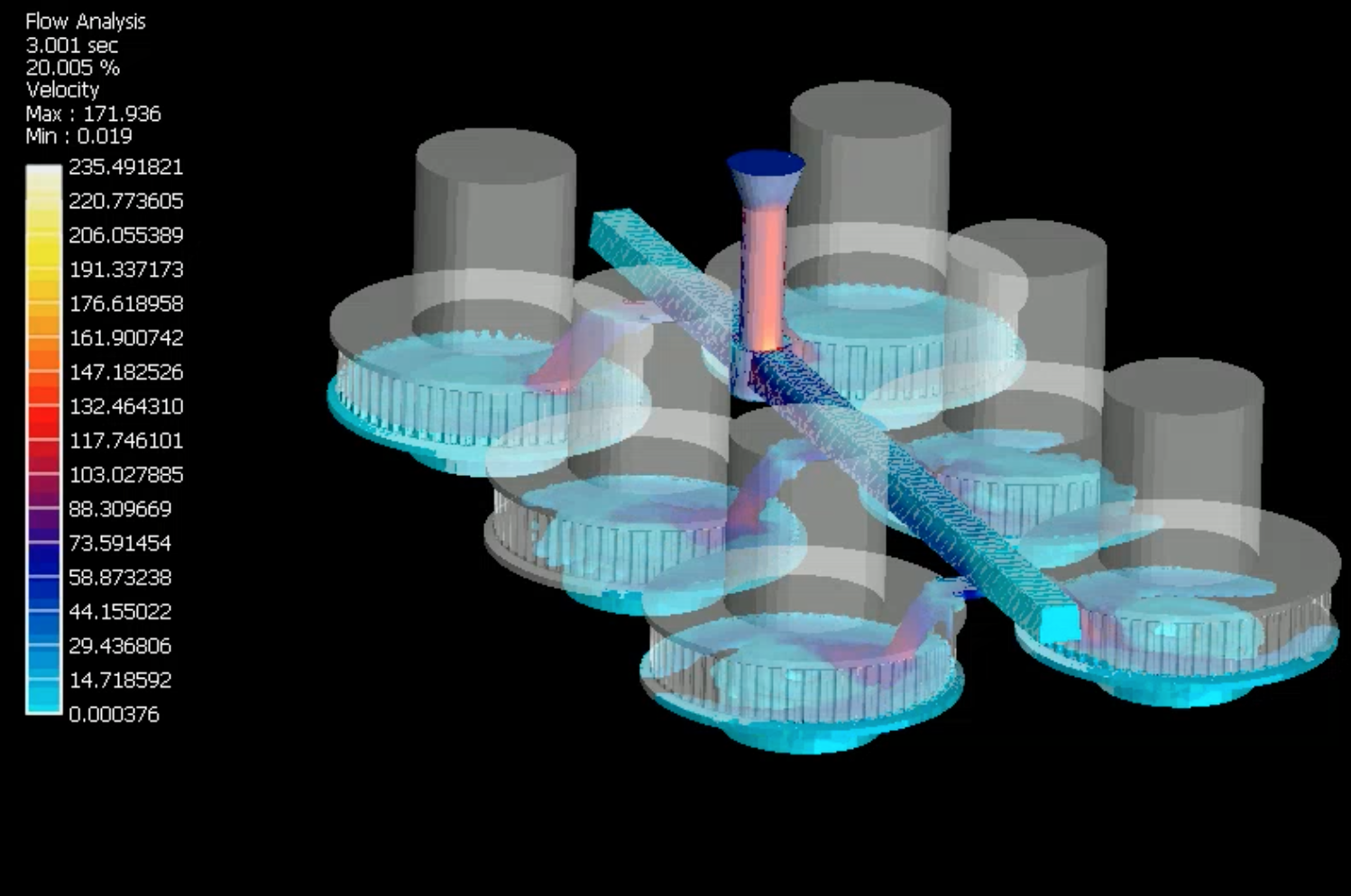

Flow Velocity 20 Sec

Simulation results of metal flow with respect to velocity to analyze sand erosion.

Flow Unfill 17 Sec

Simulation results of metal flow with respect to Unfill to analyze Gas porosity

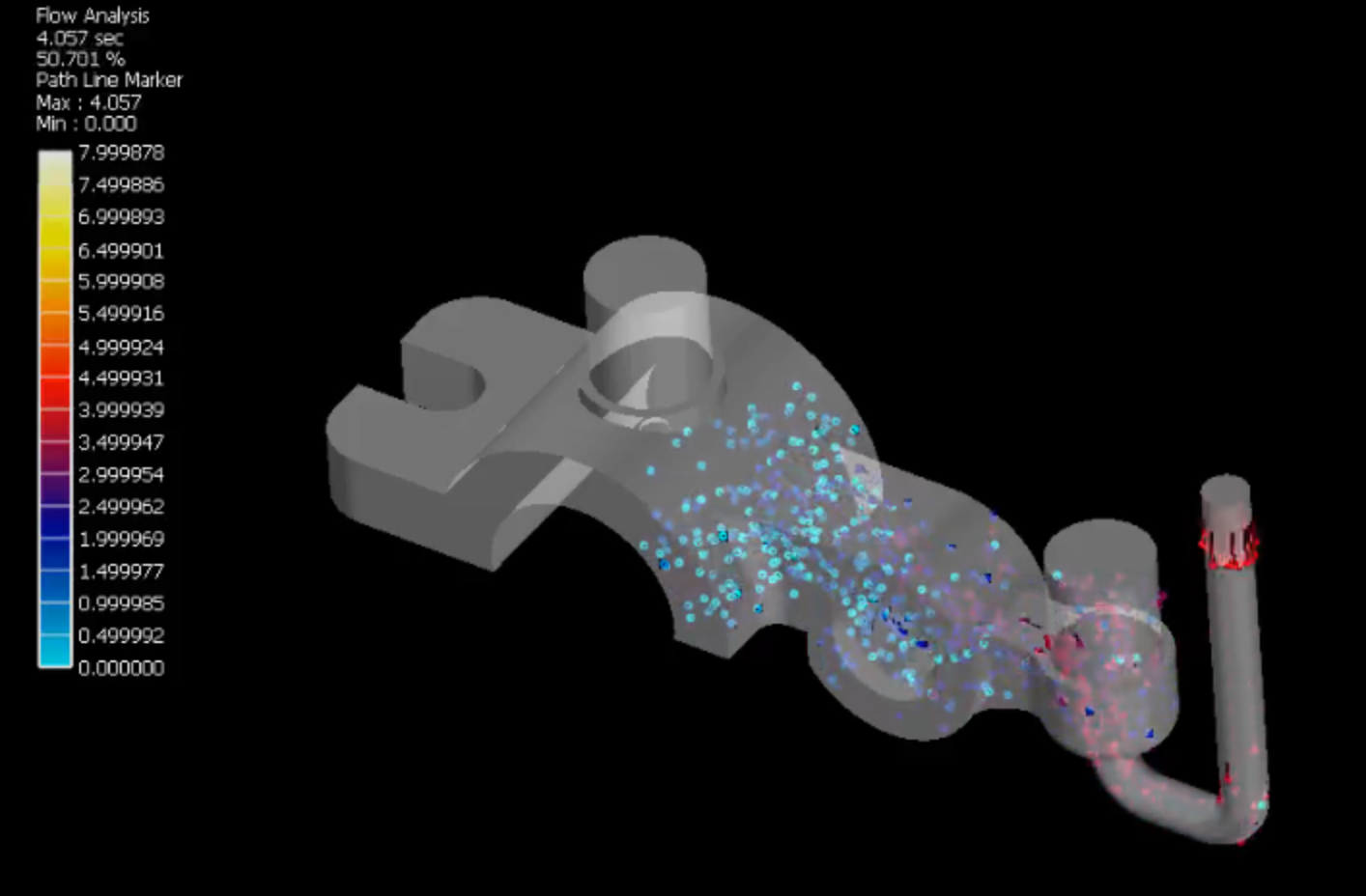

Flow Pathline 51 Sec

Simulation results of metal flow with respect to pathline shows the direction of metal entering & setlling inside the casting.

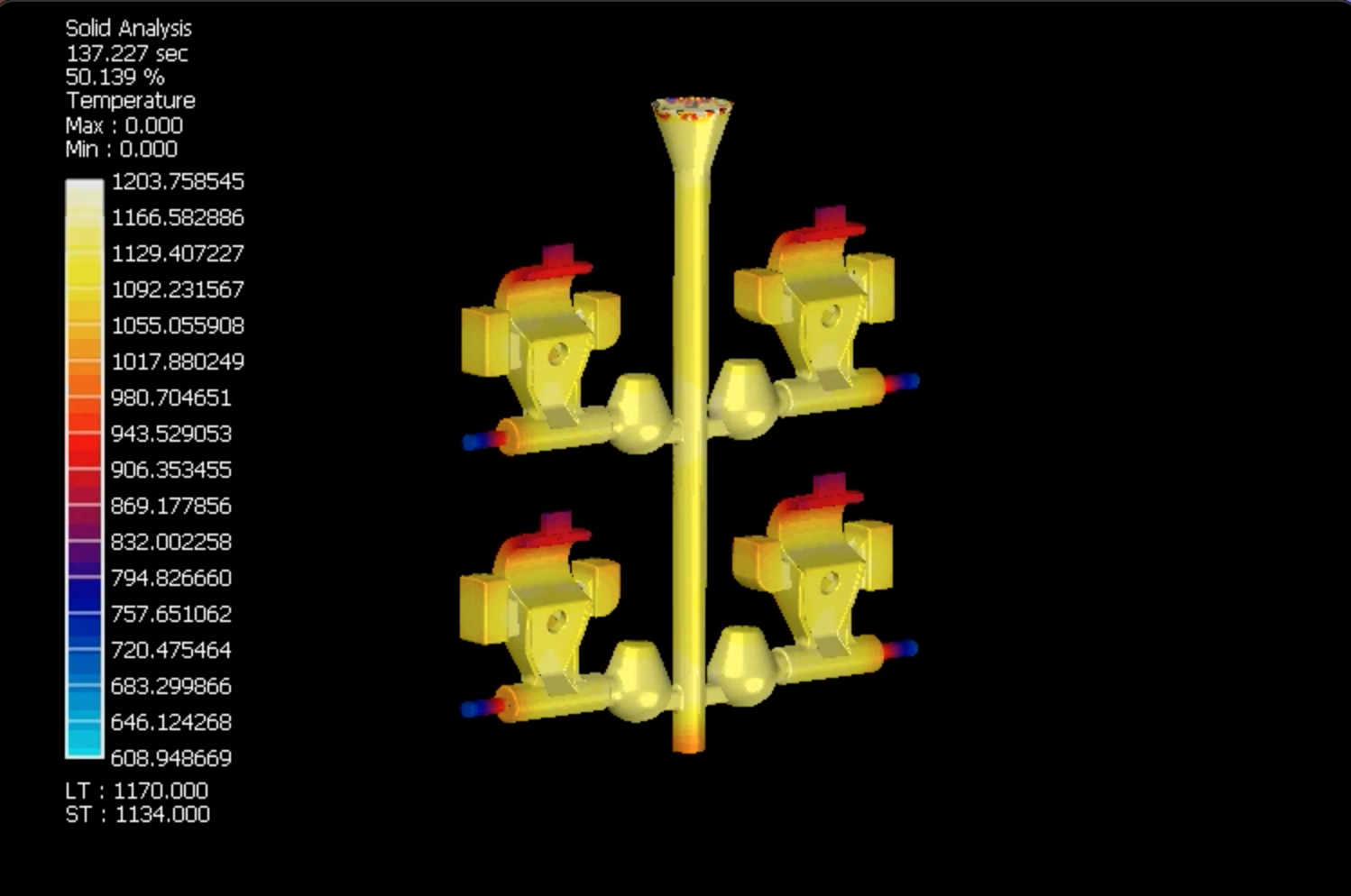

Soldification Temperature 10 Sec

The solidification temperature of a metal refers to the temperature at which the molten metal transitions into a solid state during cooling.

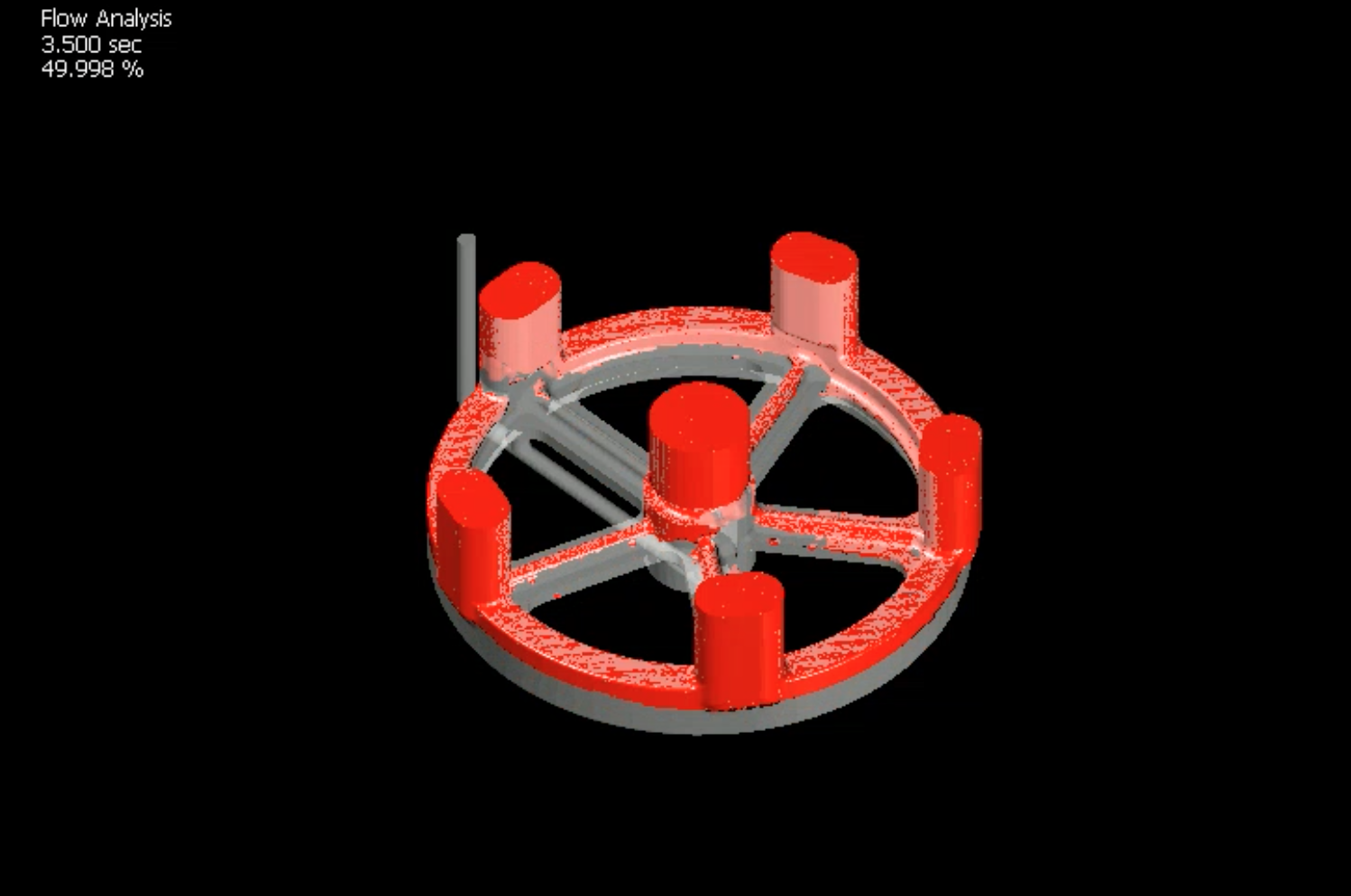

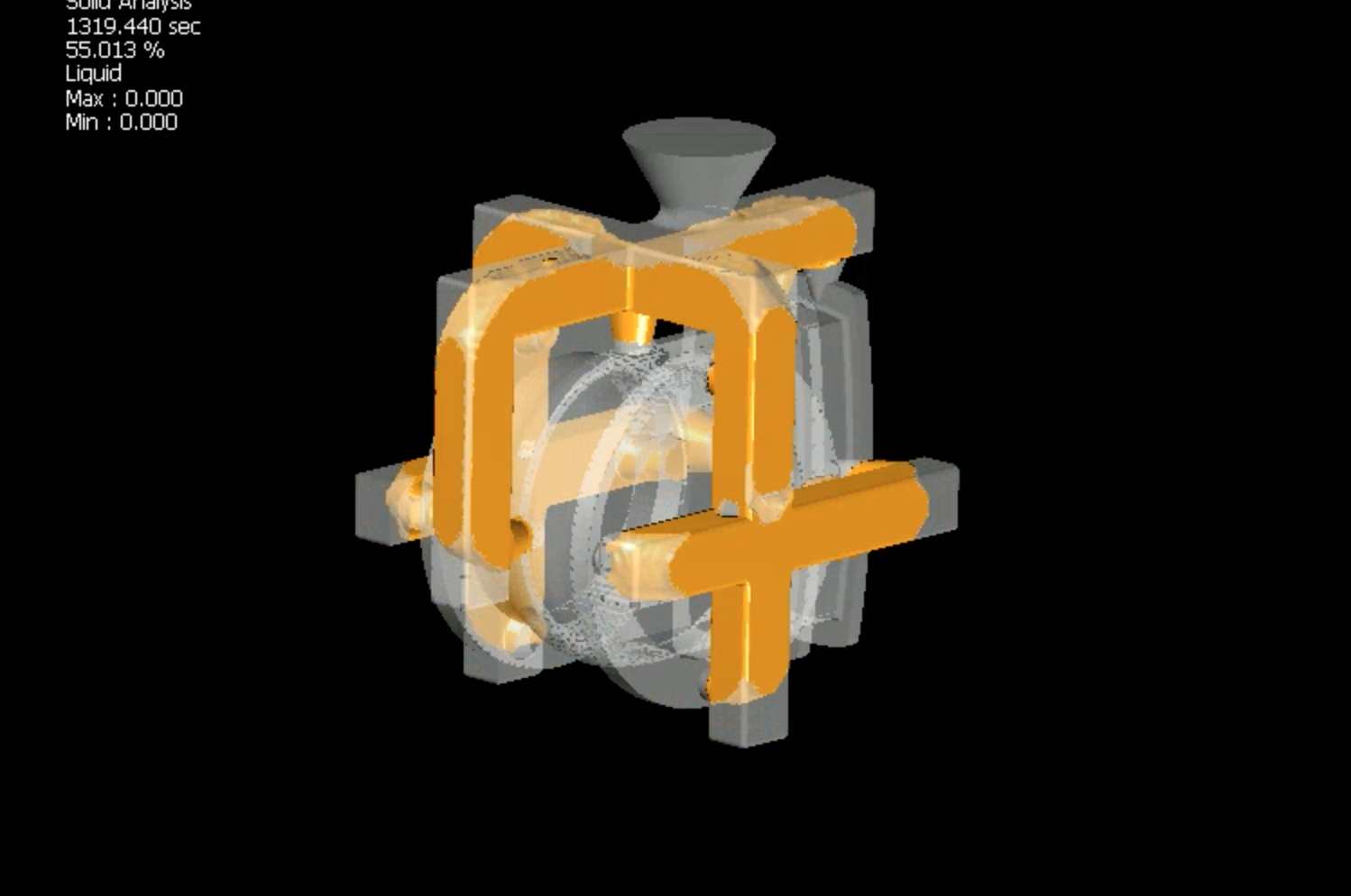

Solidication Liquid state 10 Sec

The solidification liquid state of a metal refers to the representation of start and end point of soldification.

Simulation Software

Simulation Software

Simulation Software

Simulation Software

Simulation Software

Simulation Software